|

|

The Dodge engine is re-conditioned at R & E Arnett, Doncaster. |

|

Restoration Part 19. Click here to return to the main Dodge lorry restoration page. Part of oldclassiccar.co.uk. Contact page. |

|

July 2008. The engine was dismantled in 2007, and it soon became obvious that plenty of re-conditioning would be required if the engine was ever to be reliable again. Following an epic round of metal stitching, to both the head and cylinder block, it was the turn of R & E Arnett, of Doncaster, to take on the machining required within the engine itself. The block and associated loose parts were delivered in 2008. The 'to do' list went something as follows: re-grind and polish the crankshaft, source or re-metal the big end and main bearings then machine to suit, source or have made a new set of piston rings, hone the bores, clean out the water and oil galleries, replace core plugs, replace oil seals as required, fit a new timing chain, then build up the refurbished parts into the block. Henry Arnett kept me informed as progress was made, and emailed over the photographs shown on this page. |

|

| The first photograph shows the engine and loose parts as delivered, namely the (scored) crank, bare six cylinder block, sump, and two boxes of miscellaneous parts, including the shells, rods and pistons. Having had a guided tour of Arnett's workshop, it seems quite a few of the vintage engines they get to work on arrive in boxes of parts just like this! |

|

| The crankshaft is shown here being re-ground. It was quite badly scored in places so was going to need 'the works'. |

|

| This photo shows the big end shells after casting. The small end bearings were found to be in good condition, so were left alone. As replacement bearings could not be located, the existing shells needed to be re-metalled, a tricky process especially if the shells themselves are quite thin. |

|

| Casting the shells. |

|

| Dies used in the casting. |

|

| Main bearings prior to casting. Once re-furbished they'd need to be line bored. |

|

| The mains in their dies. |

|

| Clocking up a big end in the boring machine. |

|

| Boring the big end shells to suit the crank. |

|

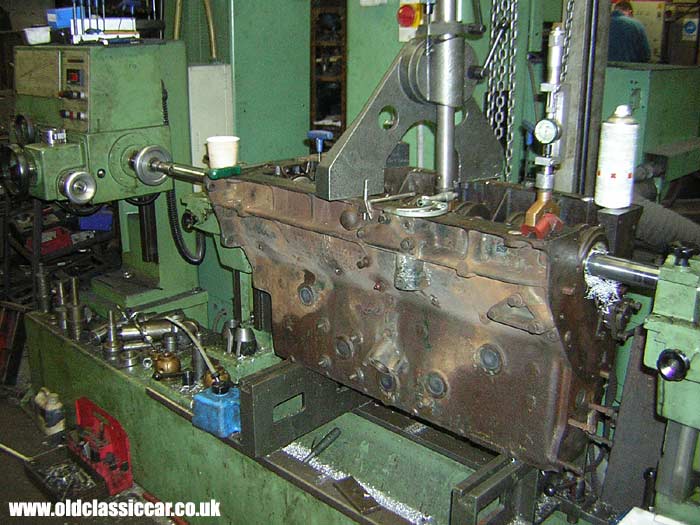

| Line boring the main bearings, bolted into the block prior to installation of the crankshaft. |

|

| A wider view, showing the Dodge's engine block mounted on the line borer. |

|

| With the crank re-ground, all that was left to do was give the journals a final polishing, prior to installation. |

|

| The engine as collected from Arnett's in August 2008, now back at VHC and requiring final re-assembly and painting. |

| A look around Arnett's workshops shows that they can turn their hand to pretty much any engine that should turn up, and judging by the condition of some engines that they've received, I find it amazing that they can be reclaimed at all. If it wasn't for engineers like this still being in business, and willing to take on slightly oddball old engines such as mine, it would be all-but impossible to resurrect these units once they'd come to the end of their working lives. More information on the engine re-furbishment services they offer can be found on the Arnetts.co.uk website. |

|

Engine, summary of work done so far. To date the engine has had the following work done to it: Numerous cracks metal stitched in the block (including down behind a cylinder liner, and the liner replaced), plus a section of casting along the top of the head replaced with new. Waterways cleaned and ceramic coated, valve seats re-cut/replaced, and the engine pressure tested. New piston rings made and installed, cylinders honed, main and big end bearings re-metalled, crank ground and polished, mains line bored, new timing chain & core plugs fitted. |

|

Return to the Dodge lorry restoration page for more info on this rebuild. Previous Page: Part 18 - Moving the Dodge to the new workshop. Next Page: Part 20 - Coachwork - installing the new ash sections. |

|

|

Custom Search

|

|

| Old Classic Car (C) R. Jones 2026. Content not to be reproduced elsewhere. |

| Website by ableweb. |

| Privacy Policy, Cookies & Disclaimers |