|

|

Lifting out the sidevalve engine from the Dodge chassis. |

|

|

Restoration Part 2. Click here to return to the main Dodge lorry restoration page. Part of oldclassiccar.co.uk. Contact page. |

|

|

Shortly after being delivered to the workshop, work began on removing the engine and gearbox from the chassis. The engine, an all-iron 6 cylinder sidevalve petrol unit, is 5.4 litres (331 cu. in.) in size. The gearbox, unlike those found in 1/2 and 3/4 ton trucks, is a five speed unit, transmitting power to a single speed rear axle (I think a twin speed rear axle was an option for the 3 ton VK range). First job was to remove the engine ancillaries, including exhaust and inlet manifolds, carburettor (Stromberg SF-3), oil filter housing, fan, dynamo and starter (6 volt Auto-lite), and then prepare for the 'big lift', courtesy of a lorry-mounted crane sourced locally. The pictures below tell the story. |

|

Viewed from the front, the Chrysler-built 331 straight six, still here with its four blade fan fitted, but the radiator removed. Just in view is the exhaust system that I had made, based on the crumbling remains of the original system. One thing I am missing is an air-cleaner for the Stromberg (not Carter) carburettor, so if anyone finds one in a scrapyard in the US, please let me know. |

|

This photo shows the nearside of the engine, before the ancillaries were removed - namely the starter and oil filter housing, alongside the steering column, which itself was repaired some years back following vandals who hacksawed the top of the column off, disappearing with the steering wheel in the process (grrr). The black box on top of the cylinder head, routes the plug leads to the correct plug. |

|

Seen a little later, the same side of the power unit with various parts removed. Note a couple of other project vehicles in the background. A correct base-mounted 6v coil is shown fitted to the bulkhead, with a temporary 12v unit hung alongside. Plan is to stick with 6v electrics. |

|

The 5 speed gearbox while still fitted in the Dodge, with floor panels removed. The pedals were still fitted at this point, and the remains of the dog-eared wiring can also be seen, hanging down from behind the dashboard. I think a new wiring loom will be required! |

|

The 'big lift' begins, using a suitably heavy looking crane. The engine and 'box came out together, and will be split once out. |

|

Another view showing the crane in position - no weedy little engine hoists used here!! |

|

Safely out and on a pallet. Work has begun removing the bellhousing and clutch assembly in this photograph. |

|

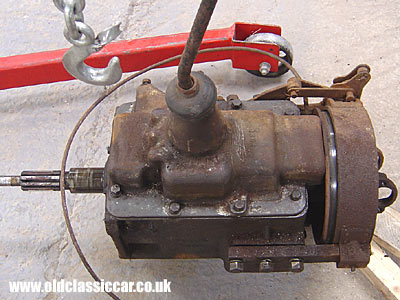

Closer-in view of the 5 speed gearbox, shortly after being lifted out of the Dodge's chassis. Also visible on the right hand side of the unit, is the contracting transmission brake band (instead of a traditional handbrake). News is that the 'box looks nice and clean inside, so thats encouraging. |

|

Another quick view of the Dodge, now without engine and gearbox for the first time in at least 50+ years, maybe even longer. With the engine out of the way, it'll make cleaning and painting of the chassis a lot easier. |

|

Over to one side a quick peek at just some of the parts removed by this stage. Included on the floor are the radiator, steering wheel, old seat (not the original), exhaust manifold, dynamo, and other bits and pieces. The bonnet is standing to the right, with a Bentley chassis rail just visible right at the back. |

|

Still attached to a crane (a smaller one this time), the cylinder head has been removed, exposing the bores within. The bores look good, as do the pistons which hopefully will clean up ok and be re-used. The block will need cleaning inside and out, before a fresh coat of paint. New seals and gaskets will of course be fitted. |

|

A close-up showing the combustion chamber of the flathead 'six'. The tiny hole has been identified after some head-scratching early on - a special tool, operated from above the head, descends into the chamber to allow accurate measuring of TDC (top dead centre) when timing the engine. Further work on the engine will follow in a later episode! |

|

Return to the Dodge rebuild homepage for more info on this old lorry. Previous Page: Part 1 - Transporting the Dodge to the workshop. Next Page: Part 3 - Stripping the rear coachwork and floors from the 'bus. |

|

|

|

Custom Search

|

|

| Old Classic Car (C) R. Jones 2026. Content not to be reproduced elsewhere. |

| Website by ableweb. |

| Privacy Policy, Cookies & Disclaimers |