|

|

Dismantling of the six cylinder Chrysler engine. |

|

|

Restoration Part 5. Click here to return to the main Dodge lorry restoration page. Part of oldclassiccar.co.uk. Contact page. |

|

|

With the engine removed from the truck, it was time to start stripping it down. The guys at VHC had already removed the ancillaries and cylinder head by this point, and it was the turn of the main engine block to be dismantled. Before this could be done, it had to be de-greased as 50+ years of clag had accumulated. An initial inspection of the engine suggested that it wouldn't be needing much work, however further dismantling proved this not to be the case sadly, as the text below will outline. The crankshaft was removed, as were the inlet and exhaust valves. It had been hoped that the valves could be lapped back in, and the bottom end cleaned and built back up. Again, this wasn't going to be an option.. |

|

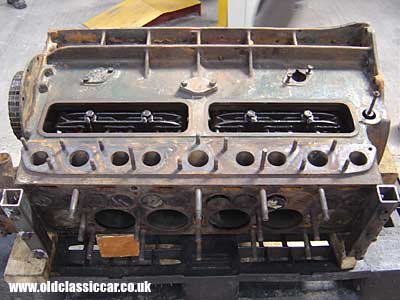

This photograph shows the cleaned block shortly after being removed and de-greased. The valves and pistons were still fitted at this time. Unlike nearly all other Dodges in preservation, the VK uses the T124 series engine, displacing 331 cu inches (5.4 litres) with a 3 3/4" bore size. Finding parts to suit this particular Chrysler engine is proving to be less than easy. |

|

Early view of the bottom end, with sump and oil pump removed, and crankshaft still in place. The condition of the crank would only become known once the bearings had been removed. |

|

Rear end of the sidevalve engine block. Just visible, above the crank, is a leaking core plug that was previously hidden by the gearbox bellhousing. If the engine hadn't been removed and stripped, this wouldn't have come to light until the small leak had developed into something altogether more problematic. All core plugs will be replaced anyway, just in case. |

|

Bottom end now being dismantled, bearings removed and highlighting some wear that will require machining. However this would only be the start of the problems that would be found with the block! |

|

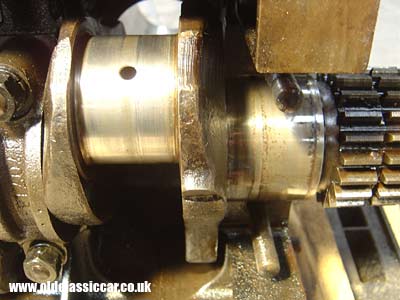

Close-up of the crankshaft, showing some scoring that has occurred to the journals. A re-grind will now be required, as will sourcing of oversize bearings. The parts supply situation for this engine is far from good, and finding new bearings could be a problem. |

|

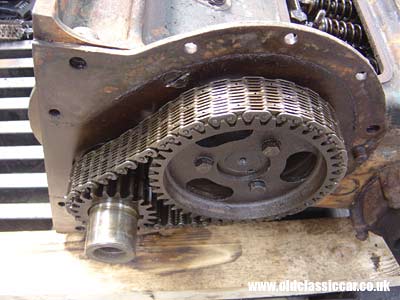

Quick look at the front end of the block prior to the crank being removed. The timing chain is a hefty affair and shows no sign of wear. However I have a new one in stock so it'll be replaced just to be on the safe side. |

|

4 of the 6 pistons now removed and sat on the floor, along with the sump and timing chain. One of the rings broke while the pistons were being removed, so new ones will need sourcing. Details of the work done to the head and block will be outlined in more detail later. |

|

Return to the Dodge truck rebuild page for more info on this restoration. Previous Page: Part 4 - Assessing the removed body panels. Next Page: Part 6 - Metal stitched repair to the cast iron head. |

|

|

|

Custom Search

|

|

| Old Classic Car (C) R. Jones 2023. Content not to be reproduced elsewhere. |

| Website by ableweb. |

| Privacy Policy, Cookies & Disclaimers |