Classic cars forum & vehicle restoration.

|

|

| Author |

Message |

ukdave2002

Joined: 23 Nov 2007

Posts: 4104

Location: South Cheshire

|

Posted: Fri Jun 24, 2022 10:43 am Post subject: Fitting Electronic Ignition...reliably? Worth it? Posted: Fri Jun 24, 2022 10:43 am Post subject: Fitting Electronic Ignition...reliably? Worth it? |

|

|

I started this post in the “what did you do in your car today” thread, but started a new thread as it may be useful for anyone contemplating fitting electronic ignition to an older vehicle.

I recently managed to source a NOS distributor for my Bedford CA; the original one fitted has worn bearings causing the dwell to wander, I will repair the original distributor and keep it as a spare.

The rest of the ignition system; coil & leads look a tad tired, so I thought an ignition refurb is in order, this got me thinking about fitting electronic ignition. I thought some of the thought process, modifications and logic may be of use to others.

I will only fit electronic ignition if it’s an improvement and going to be reliable, I don't understand people who fit electronic ignition simply because it saves adjusting the points; in the hour or so it’s going to take to fit, the points could have adjusted or replaced a dozen times!

Electronic ignition, adds complexity and if it fails not as easy to fix at the roadside, It’s worth reminding ourselves why we would bother fitting;

1. The transistor switch is much cleaner and faster than points, the benefit of this is that the magnetic field in the coil collapse more quickly with a resultant more punch (a very exaggerated analogy is the difference in energy release of a slow puncture compared to a blowout)

2. The transistor can switch a greater current than traditional points, meaning that a lower resistance coil can be fitted, the lower the resistance the faster the coil charges, resulting in more energy being stored in the coil during the dwell period.

To really maximise these benefits the plug gap can be opened up (20% larger is a good starting point) this will force the HT voltage up, so its important that the rest of the ignition system is in good fettle.

The design of aftermarket electronic ignition (or Transistor assist as it used to be called) hasn’t really changed for 40+ years, sometimes the points are retained as a trigger, in other examples they are replace with optical or magnetic triggers, ultimately they all offer similar performance benefits. One thing to watch when purchasing an after market unit is looking at what the maximum switching current is, there tends to be 2 levels, one will allow the use of a coil down to 1.5Ω the other, typically market as “High Energy Ignition Units” will allow the use of <1Ω coils.

I suspect all of these aftermarket units come out of the same factory, so being a cheapskate I went directly to a manufacturer in China and for £24 delivered received my “High Energy” Ignition unit, time will tell if this was a wise purchase!

To compliment this unit I have bought a Lucas DLB198, 0.7Ω coil. You will see coils marketed with all sorts of fancy names; Flame Thrower, Blaster, High Energy, all good products, but always worth checking that the primary resistance is <1Ω .

I mentioned reliability, and at any classic car meet there be someone who has had electronic ignition failures, sometimes multiple times, sometimes with very expensive units or replacement distributors! There are a couple of things that electronic components really don’t like:

1. Heat

2. Electrical spikes

I’m going to make 3 modifications to the distributor, one will help set it up and the other two to improve reliability.

1. I’m fitting a LED to the electronic ignition output, this will help setting as it will only light up when the distributor is “charging” the coil (dwell cycle), I may leave this inside , or drill a 5mm hole in the dizzy casing (tending to the latter)

2. Switching to a 12V 0.7Ω coil is going to draw circa 17A, this will generate some heat, so the unit its self will have some heat sink compound between it and the distributor base, and I have also added a small heat sink, attached to the side rather than the top because I don’t want any HT jumping down to the distributor base.

3. Electrical noise is probably the biggest killer of electronic devices in classics vehicles, especially where they retain electro mechanical voltage regulation (dynamo’s). Transient voltages are generated by anything that has a coil; relays, windscreen motors, electric fuel pumps etc, these transient voltages can be several hundred volts and electronics don’t like it. So I’m fitting a transient-voltage-suppression (TVS) diode across the units supply.

Total cost of these mods is less than £1

_ee_mods.jpg)

Finally if you are still awake! The original wiring to the coil is going to require some attention, when Bedford built the van (or Lucas designed the loom) it was fitted with a 3Ω coil, that would draw circa 4A, the original ignition cable looks like 14/0.30, 1.0mm², rated at 8.75A, clearly my new coil is going to take twice this current, so I need to upgrade the wiring and also protect the ignition switch which wont have been designed to switch 17A. To do this I’m going to add a relay, the relay coil will be controlled by the existing ignition to coil wire (the SW cable) conveniently I can pick up a direct battery feed from an unused terminal on the RB340 control box that is situated near the coil, and have bought some correct colour (White with black trace) 44/0.30 thin wall cable

I'll make up some new ignition leads as well, and post on the results!

Dave |

|

| Back to top |

|

|

Miken

Joined: 24 Dec 2012

Posts: 544

|

Posted: Fri Jun 24, 2022 11:29 am Post subject: Posted: Fri Jun 24, 2022 11:29 am Post subject: |

|

|

I read somewhere that one thing to avoid early failure is to not switch on the ignition and leave it on without starting the engine. Start the engine as soon as you can.

Is this correct? |

|

| Back to top |

|

|

alastairq

Joined: 14 Oct 2016

Posts: 1950

Location: East Yorkshire

|

Posted: Fri Jun 24, 2022 12:12 pm Post subject: Posted: Fri Jun 24, 2022 12:12 pm Post subject: |

|

|

Thanks for that one, Dave!

I have a Hall effect trigger on my Dellow.

Aside from that, the coil is an indeterminate make, which came with the car [on points]....For no other reason than I don't know what the output of the ignition trigger is, in order to fit a low ''ohm-age' coil...{? non electronical tyro]

I opted for the Hall effect system because it came as a kit with the correct [eventually] backplate, and I didn't know better [still don't know better, either]..I think it was an Accuspark kit, but they don't advertise my particular kit any more..[Ford 100E, with flat edged baseplate]

I have 'known' about points-versus-hall effect [or optical triggers] for many years now....When I was trialling a Skoda Estelle, with a ''tuned' engine, one of the things the rally lads passed on was, how inconsistent the actual ignition timing became at higher revs.

Whilst full advance to required specs was achieved [and at what revs?], a strobe light showed how much the timing actually danced around on the timing marks at those required revs!

All down to the inconsistency of performance of a steel spring.Plus, the wear abilities of the actual contacts.

Back then I used a 'slicer' system as used by Skoda on the FAvorit [which had the same engine]....although there were issues with the Skoda FAvorit module getting too hot when used at the rear of the car, as in an Estelle....I pinched a computer fan to sort that issue, but a Skoda enthusiast [in the club] had developed a sealed unit which was impervious to the higher engine bay heat. Certainly made the accurate setting of full advance much easier.

Most modern engines of the time used the hall effect system [cheaper to make?} to replace points. [Volvo, I noted at the time]

I will try to find a small heat sink, to follow your advice...since the sidevalve Ford engines seem to make the distributors very hot [heat soak, being right on top of the cylinder head]

Mine does have that white goop under the sensor....but I do wonder how long it lasts? Any ideas?

An issue I always noted when thrashing the earlier Ford [ten Horse] side valves was the tendency for the crankcase to pump oily fumes up into the distributor. despite having plenty of other ventilation [including a vent on the fuel pump blanking plate] MAybe mine revved too high for its own good [easy 5500 rpms]...Anyway, with points I noted how easily a gobbitt of oil would find its way between the points contacts.....only took fumes, no real oil deposits..but enough to boogah things about....

Hall effect unit stopped this misbehaviour instantly.

BAck in the early 1990's I also braved buying a set of 'special' plug leads from a US ignition company [Nology].

They claimed much the same effect as you describe regarding bigger charge build up..The leads contained a flexible capacitor material built in [made them thicker], with each individual lead also having an earth strap.

I have no idea whether this was all moonshine or not, as I didn't conduct back-to-back experiments, but I do know I got well over 50 bhp out of it on a rolling road, with nowt more than an 8 horse cylinder head, twin 1 1/8ths SUs on a home made manifold, Aquaplane exhaust manifold, and these plug leads.

Oh, and a little bit of transfer port relieving of my own...

A link to the nology plug leads advert, still much the same as back in the 1990's..

https://www.nology.com/hot.html

They tailor made my leads to suit the sidevalver...

I have not had much inthe way of unreliability ....and have noted vastly improved starting hot or cold.

On my Mustang 6 pot, I purchased a proper electronic distributor [TCS, as it happened, the cheapest I could afford, being on a pension]...I opted for the slim line version , which required a separate coil..the normal versions use the GM HEI system [on modified ally bases]...which is quite bulky, as the coil[HT] is built into the distributor itself.....it has no 'king' or centre HT lead, whereas, mine does, but with a lot less bulk, so fits the engine easier.

I forget what the output i offhand, but it is high enough to support a 0.7 ohm coil[from Real Steel, quite a bit cheaper than something with a fake Lucas sticker on its side]...

The spark plugs are gapped to nearly 50 thou...which, i understand, is on the 'conservative' side...[originals were about 20-25 thou, I forget offhand]

Again, starting is a breeze providing the fuel pump is allowed to churn itself up a bit if left standing for a while......an electric pump would sort that issue out.

Anyway, I have no qualms about using 'technology' to improve what went before.

Especially given that fuel, for example, is so very different in make up, compared to the petrol of the 60's or 70's anyway.

Or, brake lining materials?

Or a myriad of other stuff available today, which wasn't on the horizon back when our oldies were made?

Another issue probably worth mentioning is, the dubious quality of essential service items available today [having been made to a specification in China?}..

We all know about issues with buying a 'new' condenser, or points, or whatever, today....and the variable quality of such items?

Maybe because those who set out to get stuff made, reckoned we wouldn't be driving more than a couple of hundred miles a year, if that? So wouldn't 'notice' the lack of quality and unreliability that ensues when our oldies are used, almost, ''normally?''

Going to hall effect ignition to replace the points is to me, a good idea.

It's not about 'fit & forget' or servicing issues.

To me its about improving the efficiency & 'performance' [starting, etc] of what we have.

I haven't touched about the [to me?] marvelous electronic advances in ignition control available to those with the likes of MGBs, etc...where on can select one of a number of 'maps' programmed onto the modules to optimise the performance of one's engine to suit what other engine work one has done.

Got to be a lot 'easier' than playing around with advance springs in the distributor, to get the most appropriate advance curves, to take 'advantage' of stuff like, today's petrol?

A pal fitted such a unit to his MGB which he'd had for decades...and was amazed how, by playing around with the various maps, he was able to obtain a far smoother, stronger performance from the B series, with much improved fuel consumption....

The old technologies were always going to be something of a compromise in terms of engine performance & efficiency.

[How many old car owners still religiously stick to the maker's static, or idle, timing, regardless.....? Instead of using it as a starting point, and conducting their own ''timing swinging'' sessions to find their own engines'' sweet spots?]

_________________

Dellow Mk2, 1951 built, reg 1952.

Fiat 126 BIS

Cannon special [1996 registered. Built in 1950's]

----------------------------------------------

Ford Pop chassis, Ashley 1172 bodyshell, in pieces. |

|

| Back to top |

|

|

alastairq

Joined: 14 Oct 2016

Posts: 1950

Location: East Yorkshire

|

Posted: Fri Jun 24, 2022 12:14 pm Post subject: Posted: Fri Jun 24, 2022 12:14 pm Post subject: |

|

|

| Miken wrote: | I read somewhere that one thing to avoid early failure is to not switch on the ignition and leave it on without starting the engine. Start the engine as soon as you can.

Is this correct? |

Probably not specifically to do with electronic ignition systems, but everything to do with the coil, regardless of what the triggering system is?

The coil will heat up if sat with the ignition ''on''...which can be detrimental to the coil.

Always wise to disconnect the coil if intending to leave the ignition on for any reason or length of time..

_________________

Dellow Mk2, 1951 built, reg 1952.

Fiat 126 BIS

Cannon special [1996 registered. Built in 1950's]

----------------------------------------------

Ford Pop chassis, Ashley 1172 bodyshell, in pieces. |

|

| Back to top |

|

|

Ray White

Joined: 02 Dec 2014

Posts: 6303

Location: Derby

|

Posted: Fri Jun 24, 2022 1:46 pm Post subject: Posted: Fri Jun 24, 2022 1:46 pm Post subject: |

|

|

| alastairq wrote: | | Miken wrote: | I read somewhere that one thing to avoid early failure is to not switch on the ignition and leave it on without starting the engine. Start the engine as soon as you can.

Is this correct? |

Probably not specifically to do with electronic ignition systems, but everything to do with the coil, regardless of what the triggering system is?

The coil will heat up if sat with the ignition ''on''...which can be detrimental to the coil.

Always wise to disconnect the coil if intending to leave the ignition on for any reason or length of time.. |

Just one of the little things you must remember to do if you have a car old enough to not have an ignition key is to switch off. On more than one occasion I have forgotten and found a flat battery on my return. The coil gets hot before the battery is dead. |

|

| Back to top |

|

|

badhuis

Joined: 20 Aug 2008

Posts: 1390

Location: Netherlands

|

Posted: Fri Jun 24, 2022 2:40 pm Post subject: Posted: Fri Jun 24, 2022 2:40 pm Post subject: |

|

|

Thank you Dave, for a well written topic. Good to have a knowledgeable person explain these kind of things.

_________________

a car stops being fun when it becomes an investment |

|

| Back to top |

|

|

Ray White

Joined: 02 Dec 2014

Posts: 6303

Location: Derby

|

Posted: Fri Jun 24, 2022 3:01 pm Post subject: Posted: Fri Jun 24, 2022 3:01 pm Post subject: |

|

|

Dave's point about WHY people go for electronic over points etc. is relevant to me. I chose to "upgrade" my electrics believing, at the time, that it would be far more reliable.

I have since learned that I may well have been mistaken as almost all the people with electronic distributors have the original one in the spares box and take it everywhere they go! |

|

| Back to top |

|

|

Rick

Site Admin

Joined: 27 Apr 2005

Posts: 22437

Location: UK

|

Posted: Fri Jun 24, 2022 4:54 pm Post subject: Posted: Fri Jun 24, 2022 4:54 pm Post subject: |

|

|

Funnily enough only yesterday evening I was looking at the MGB's dizzy pondering over whether to change it back to a more conventional points type affair, rather than whatever it has fitted at the moment which looks a) a bit complicated and b) a bit old.

I don't pretend to understand the technicalities of what you're doing Dave, but many thanks for putting together such a detailed overview of your plans.

RJ

_________________

Rick - Admin

Home:https://www.oldclassiccar.co.uk

Videos:https://www.youtube.com/user/oldclassiccarRJ/videos

OCC & classic car merchandise (Austin, Ford ++):

https://www.redbubble.com/people/OldClassicCar/shop |

|

| Back to top |

|

|

MikeEdwards

Joined: 25 May 2011

Posts: 2467

Location: South Cheshire

|

Posted: Fri Jun 24, 2022 6:19 pm Post subject: Posted: Fri Jun 24, 2022 6:19 pm Post subject: |

|

|

Interesting to read this, as I'm getting around to swapping my Sportshatch to run Lumenition. I will have to come back and read it in more detail at some point as I'm sure it touches on stuff that I haven't considered.

My main reason for doing that is that I'm having trouble with the points, while it doesn't take all that long to adjust them it seems to need doing quite frequently. I believe the Delco distributor is pretty bad for wear leading to a lot of play in the main shaft, which then causes trouble with points gap / dwell angle. I've gone for Lumenition simply because that's what I have on the Firenza, and I've got all the bits for it. I'll have the old distributor in the boot "just in case" for a few years, though.

_________________

1976 Vauxhall HP Firenza, 1976 Vauxhall Sportshatch (x2), 1986 Audi coupe quattro, 2000 Audi TT |

|

| Back to top |

|

|

ukdave2002

Joined: 23 Nov 2007

Posts: 4104

Location: South Cheshire

|

Posted: Sun Jun 26, 2022 5:47 pm Post subject: Posted: Sun Jun 26, 2022 5:47 pm Post subject: |

|

|

There is no doubt that electronic/ transistor assist will improve spark quality; the question when deciding if to fit it is "do I really need to improve the spark?"

The faster an engine runs, the less time the coil has to charge, above 3000 RPM the coil energy reduces. More cylinders also reduces dwell time.

Starting; the ability to open up the plug gap will force a higher HT voltage, this will both assist starting and assist firing fouled plugs. (Clearly if the plugs are fouled this suggests another problem)

Anything running 6v electrics is compromised, original points are rated at a maximum of 4A before they start to wear quickly, 6V @ 4A will only get 50% of energy into the coil when compared to a 12V system.

That said I know of 100's of folk running on 6V without an issue

What I am unclear about is how the burn of E5/E10 fuel affects our ignition choices, what do we want from our ignition? advance/retard, longer or slower burn?

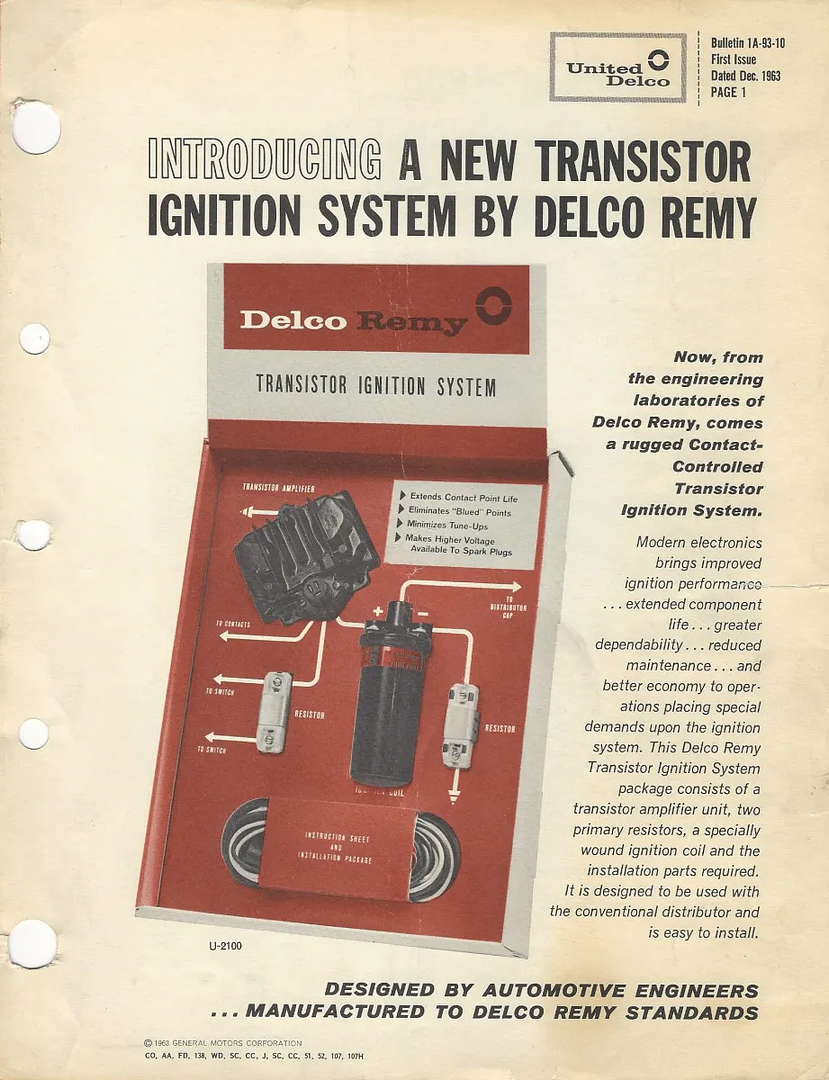

In case you thought electronic ignition / transistor assist is modern? it was 60 years ago!!!

Dave |

|

| Back to top |

|

|

alastairq

Joined: 14 Oct 2016

Posts: 1950

Location: East Yorkshire

|

Posted: Sun Jun 26, 2022 8:04 pm Post subject: Posted: Sun Jun 26, 2022 8:04 pm Post subject: |

|

|

| Quote: | | What I am unclear about is how the burn of E5/E10 fuel affects our ignition choices, what do we want from our ignition? advance/retard, longer or slower burn? |

I've mentioned this before, but take a quick look [maybe, sign up, and ask a question?] at the site I've linked below?

https://classicenginesmodernfuel.org.uk/Default.aspx?dyn_menu_mainmenu=1000001

IIRC, the ignition ought to be advanced a bit more?

BTW, the above applies regardless of the petrol, given the content of today's fuels [last 25 years or so].

As any motor manufacturer will tell us, electronic ignition [either hall effect, or simply a crank sensor, [and all the other sensors]...or an optical timing disc[chopper on crank pulley?], plus an ECU [Megajolt, for example] which can be programmed to give the optimal ignition timing at all rev points, under all condidions....is far more efficient, better, and cheaper to manufacture to give consistent performance, year on year..

Points, bob weights, and even a vacuum advance are all subject to wear & tear, manufacturing anomalies, etc, thus are a compromise at the best of times.

[Hence why I proffered that manufacture's' ignition timing figures can really only be a starting point. As soon as the various components start to wear, or the fuel starts to alter in it's components, or the weather changes permanently, those initial timing figures will not be right for that particular engine, under those particular circumstances. Hence, a hour or so spent out on a quiet road, 'swinging the timing', can lead to improved efficiency, at a figure which may be adrift somewhat from what the original manufacturers stated. Or, a session on a rolling road, to achieve the same thing, but that costs [more}]

Like a carburettor, yet another compromise.....good enough under most conditions, but, unlike electronic fuel injection, not good enough all the time.

_________________

Dellow Mk2, 1951 built, reg 1952.

Fiat 126 BIS

Cannon special [1996 registered. Built in 1950's]

----------------------------------------------

Ford Pop chassis, Ashley 1172 bodyshell, in pieces. |

|

| Back to top |

|

|

bjacko

Joined: 28 Oct 2013

Posts: 356

Location: Melbourne Australia

|

Posted: Mon Jun 27, 2022 8:45 am Post subject: Electronic Ignition Posted: Mon Jun 27, 2022 8:45 am Post subject: Electronic Ignition |

|

|

| I got fed up with failed condensers and changed to electronic on my Morris 8 |

|

| Back to top |

|

|

ukdave2002

Joined: 23 Nov 2007

Posts: 4104

Location: South Cheshire

|

Posted: Wed Jun 29, 2022 9:27 am Post subject: Re: Electronic Ignition Posted: Wed Jun 29, 2022 9:27 am Post subject: Re: Electronic Ignition |

|

|

| bjacko wrote: | | I got fed up with failed condensers and changed to electronic on my Morris 8 |

That will have a condenser (0.22µF capacitor) built in (unless its a CDI system)

Illustrates how poorly made "automotive" condensers are made these days.

Dave |

|

| Back to top |

|

|

Ray White

Joined: 02 Dec 2014

Posts: 6303

Location: Derby

|

Posted: Wed Jun 29, 2022 9:47 am Post subject: Posted: Wed Jun 29, 2022 9:47 am Post subject: |

|

|

| I have always found "The distributor Doctor" to be a reliable service. Martin Jay even managed to source a particularly rare set of points for my 1930 Austin (Seven) Swallow.! |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

php BB powered © php BB Grp.

|