Austin 7 components from Cambridge Engineering.

The growth of "special" building during the late 1950's led to a number of companies being formed to supply parts to the DIY car-builder. Amongst these enterprises was Cambridge Engineering who, along with firms such as Bowden, Speedex and Super Accessories, could supply all manner of tempting tuning parts to satisfy most builders' needs, and budgets. The bulk of these cars used either Ford E93A or Austin 7 running gear, and it was the latter market that Cambridge Engineering had set its sights on.

|

|

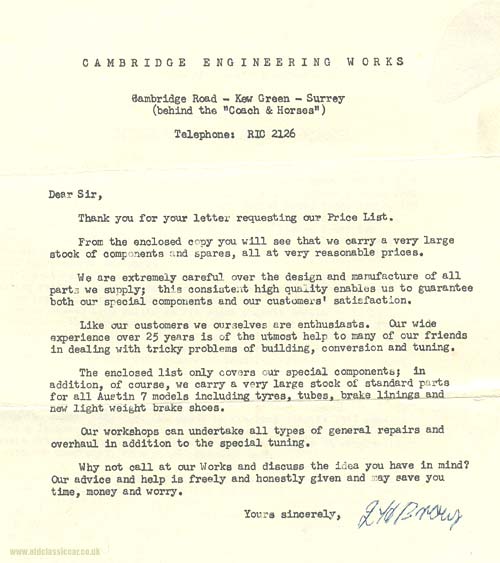

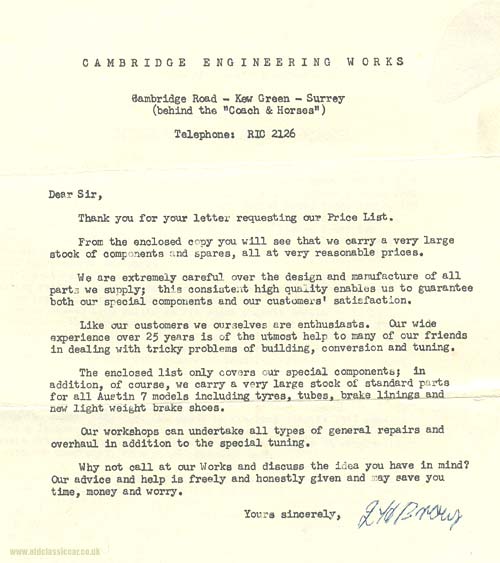

This literature dates to 1958, when the special-building hobby was perhaps at its most prolific. A letter, sent from their address on Cambridge Road, Kew Green, Surrey (behind the "Coach & Horses"), is shown below. A hotel of this name still exists, overlooking Kew Green, but do the garages that Cambridge Engineering once occupied still survive?

|

|

Price lists for Austin 7 parts.

Attached to the letter are two pages of Austin 7 Special Components, describing the products they had available. Sports two-seater bodyshells, with "... the appearance of J2 MG but without doors ..." comprising aluminium panels attached to an ash frame, cost £27 10s in standard form, or £30 for the lengthened version, designed for longer (1932 onwards) Austin chassis. Remote gearshifts, 15" and 16" wheels, lightened flywheels and four branch manifolds, to name just a few other bolt-on goodies, are also described in this price list. To view the full list for 1958, click these links Austin 7 parts Page 1 and Page 2.

|

|

A supplementary sheet mentions other items of speed equipement that they could supply. Most interesting of the lot was the ALTA high compression light alloy cylinder head, available for £6 10s 0d. Twin SU carburetters and Terry's Aero valve springs were stocked on the shelf, as were straight through - DEEP NOTE - exhaust systems.

|

Further information.

Attached to the price list is an information sheet, telling the reader more about Cambridge Engineering and their conversion parts. This is reproduced below.

|

Austin Seven Conversion.

"We of the Cambridge Engineering Works specialise in Austin 7 cars and their conversion. Having been connected with this work for the past 25 years, considerable knowledge and data has been amassed, from which we feel we are able to speak from experience on this subject. It is now common knowledge that speeds up to 80mph can be obtained from a tuned version of the Austin 7, which allows a cruising speed of 65-70mph provided that the all up weight of the car is kept down to a minimum, the main object being to obtain a good power to weight ratio from the outset.

|

|

It will be obvious that, if a light yet sturdy body, constructed mainly of alloy materials and weighing something like half the original body be fitted to the chassis, the power to weight ratio will benefit considerably. This alone in fact should bring the all up weight of the car down to something like 7 cwts. Again if the power output of the engine be increased to something like 25bhp by a few modifications it follows that a marked increase in performance will result.

|

|

The principal component for achieving this is a high compression alloy cylinder head preferably of high duty alloy to prevent distortion, this will also help to eliminate some of the extra heat resulting from the higher engine speeds. Additionally good breathing is restricted by the side valve arrangement, this can be improved to a large extent by the modification of the cylinder block and valve gear together with the fitting of twin carburetters to allow maximum breathing, providing this work is correctly carried out which is critical, increased speed and efficiency will result.

|

|

To utilise the higher speeds available with safety, it is essential to improve the roadholding and stability of the car. This calls for the lowering of the chassis by modifying the suspension and so lowering the centre of gravity essential for road-holding and cornering at higher speeds, this in turn will, of course, increase the loads on the kingpin axle eyes which should, of course, be strengthened to this end, a point which is missed by most but supplied regardless with all our lowered suspension sets. A further improvement is the fitting of smaller wheels with a wider section tyre thus reducing gyroscopic action to a minimum and reducing wear to the steering gear, at the same time improving road adhesion and ride apart from a better appearance. The lowered type of suspension if modified correctly to maker's specification which is critical, has no snags and is being used for racing and road use with highly satisfactory results.

|

|

It is an advantage to fit a smaller radiator block and shell, providing the former is quite free from obstruction, this will reduce frontal area and improve the appearance of the finished car, but the radiator should not be lowered below the starting handle, otherwise overheating will take place through the thermo-syphon action being lost.

|

|

The brakes are about the worst failing of the Austin 7, quite a lot of which is through wear and loss of leverage. The pre-1931 model brakes are the most difficult to improve but both these and the later models can be made to stop quite effectively by the use of the Bowdenex braking system which is the enclosed cable type used for the front together with long levers for the rears. The standard braking system tends to pull the front axle backwards when applied and usually jams on when on a full lock, juddering when applied reversing, all this is eliminated with the Bowdenex braking system of which we are the originators and manufacturers, the Austin can be brought right up to date by the fitting of Lockheed brakes, these are smooth and powerful in action and will give complete satisfaction with very little maintenance. [Information on hydraulic brake conversions for Austin 7s by Bowden can be found on this page]

|

|

Friction dampers can be made to work quite satisfactorily by the use of a better type of disc of the woven type, this is not affected by weather conditions and grips at all times.

|

|

These being the basic facts of Austin conversion which may help the constructor to understand the fundamental principles involved which have been proved by time and experience."

|

|

The Works was open from 8.30am until 7.00pm weekdays, and Saturdays 9.00 until 5.00pm. If any more period literature relating to Cambridge Engineering turns up, I'll add it in here.

|

|

Return to the period tuning companies pages, for more information on suppliers of modified Ford 10 and Austin 7 parts. An example of an Austin 7 special can be found on this page.

|