|

|

The engine and gearbox are re-fitted, and work continues on re-assembly. |

|

|

Restoration Part 25. Click here to return to the main Dodge lorry restoration page. Part of oldclassiccar.co.uk. Contact page. |

|

|

April saw bits and pieces done to parts off the truck, but the bulk of progress was made during May. It was during this month that VHC confirmed their wish to see the project completed by July 2009, so a new schedule was drawn up in a bid to see this happen. Undoubtably progress during May picked up and a fair chunk of re-assembly work was completed. The key achievement was re-uniting the heavy old straight six sidevalve Dodge engine and five speed gearbox with the truck, photos of which follow below. I was also lucky enough to source a matching set of little-used Dunlop tyres, perfect for the truck with a suitably old-looking tread pattern. |

|

| April saw the first coats of Westminster Green paint applied to the vehicle's bodywork, again supplied by HMG in Manchester. The plan was to get the dashboard to a final finish in order that dials could be fitted in the near future, and re-paint the bulkhead in order that the engine and transmission could be re-installed. Various coats were applied, starting with a sealer followed by primers and top coats, experimenting with matting agents and different methods of application. The idea was to leave both areas looking re-painted and smart, but avoiding an over-shiny, "boiled sweet" look. The photo above shows the dashboard after the first couple of prep coats had been applied. |

|

| While prep work continued at the front, some more work was done on trim at the rear - this photo shows the newly curved beading that fits to where the rear arch joins the body. The window frames are yet to be fitted - the new strips of window channeling made specially for the job, were cut to size and the vertical and top pieces welded together. The lower edge of the frames have to be removable to enable the glass to be fitted, so bracketry will need to be made. |

|

| The new n/s/r door is shown here being test fitted. This had to be completely made from scratch. |

|

| Now a photo with both back doors in place. Note the different methods of construction for the back doors. Although they could have been made to match perfectly, I prefered the differences to remain, a throwback to WW2 as mentioned already. Door catches still need to be re-installed, and final trimming of the window apertures remains to be done at this stage. |

|

| This view of the back end shows both doors in-situ - the original doors were in a very poor state, and would never have come up looking as straight as this. |

|

| While on the subject of the doors, both front doors by this point had been re-skinned in Zintec steel. Again window frames will be re-made using the same section channelling as used at the back. |

|

| The original 9.00 x 20 crossply tyres were shot, and re-using them was never going to be an option as their age and condition both counted against them. The truck had a mixture of road tyres and military bar-grips, some British and others American. The military tyres are a legacy from it's life with the RAF most likely. Some of the original tyres still have W^D stamped on them (War Department). A handbook for the VK series trucks specifies that both 8.25 and 9.00 x 20 tyres were standard options of the day. |

|

| I'd been looking for new tyres for quite some time, and all I could find was either odd tyres of questionable history, or new tyres from India or Czechoslovakia, both with inappropriate-looking branding on their sidewalls. Flicking through a classic lorry magazine in May turned up an advert for some Dunlop 8.25 x 20s, with tubes and flaps, and little used. One of the signwritten adverts on the side of the Dodge is for Dunlop Tyres - "The First Tyre in the World" - so a set of Dunlops on the truck would be perfect. A trip southwards secured seven of these tyres, and I delivered them to VHC the next day. Once the wheels have been blasted, they'll be painted green and the tyres can be fitted. If anyone has a spare 10 stud Budd rim (split rim type) that they no longer need, please get in touch. |

|

| Another task was to find some new fuel tank sender units. The originals were seized and rusty, so the hunt began for new ones. Dodge parts for the 1939-47 trucks aren't overly plentiful in the UK. However a look at a friend's 1940 Chevy pickup showed that it too had the same five-hole mounting layout, and later I discovered that wartime Jeeps also used the same fitting. A visit to a Jeep parts supplier secured two new senders which should do the job perfectly, once their operating arms have been extended. |

|

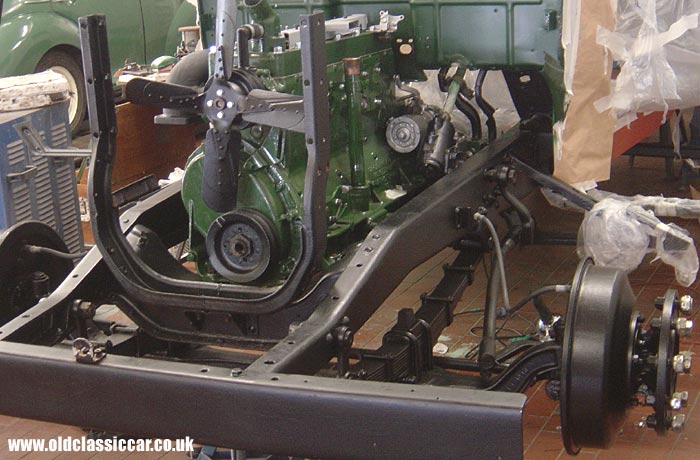

| This photo shows the newly-painted bulkhead and chassis, ready for the engine and 'box to be bolted in. They both bolt directly to the chassis, no rubber mountings like you'd find on an old car, so lining up this heavy old lump took some time, especially as the back edge of the cylinder head is a very snug fit with the bulkhead. The following photographs show the sequence of events as the engine is bolted in finally, and ancillaries begin to be re-fitted. |

|

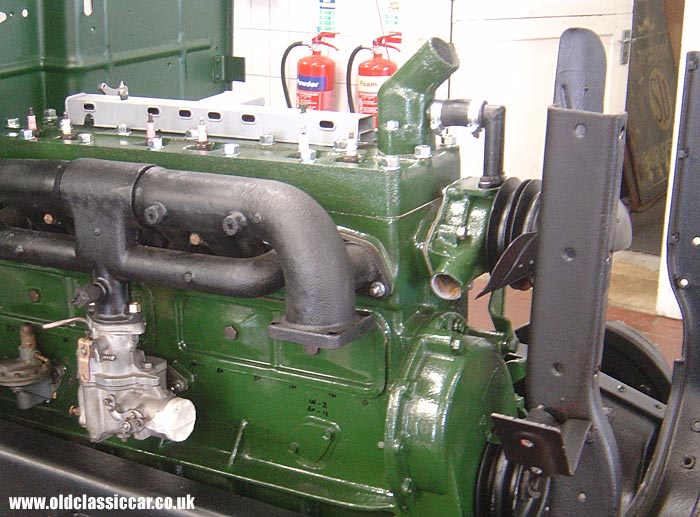

| The engine bolted into place, and viewed from the offside. The water distribution tube has yet to be finally pushed 'home' in this picture, and was awaiting the return of the re-furbished waterpump. |

|

| Engine in, awaiting ancillaries. Note the original pack of Mopar manifold gaskets for the 331 cu. in. engine - all the old boxes and packaging from the new-old-stock parts used in the rebuild are being kept. |

|

| A week or so later and some ancillaries have now been bolted back on. Arnett's in Doncaster, who did much of the engine machining, re-furbished the waterpump. Some machining had to be undertaken in order that a new seal and bearing could be used, and it is shown here back on the engine. One of my spare (new) carburettors is now bolted to the manifold. The 331 engines use a Stromberg SF-3 carburettor. I've yet to find a suitable air cleaner, so I'll probably have to find one from another vehicle that can be adapted to suit. The radiator support bracket, and the four bladed fan, are also in place now. |

|

| The newly-painted chassis and front bumper can clearly be seen in this picture. Again, the idea was to look clean and tidy without a sticky glossy look, hence the use of a satin black chassis paint from HMG. The starter has been re-fitted, as have the re-painted brake and clutch pedals. |

|

| Last photo for this page shows the extractor being used during a later application of green paint to the dashboard. Glen from HMG came down to see how progress was going on the Dodge, and between us all a plan of attack, and list of paints that would be required, was drawn up. VHC's plan is to crack on with painting the main body of the truck very soon, so all being well June should see this well and truly underway. Several possible choices of signwriter have also been discussed, and a couple of the old signwritten panels were taken away to be analysed back at HMG, to establish the shades of colour required for the livery. |

| It has been suggested that the truck be taken to a classic commercial show in July - however as I don't want to take it out until it has been completed, a final decision on that idea will have to wait til nearer the time. A test run of the engine, which can't be far off now, will give a good indication of how achievable a July completion date is, given that there is still plenty to do. |

|

Return to the Dodge lorry restoration page for more info on this rebuild. Previous Page: Part 24 - More bodywork restoration & RENU'd fuel tanks. Next Page: Part 25 - Ancillaries are overhauled and fitted in and around the engine. |

|

|

Custom Search

|

|

| Old Classic Car (C) R. Jones 2025. Content not to be reproduced elsewhere. |

| Website by ableweb. |

| Privacy Policy, Cookies & Disclaimers |