|

|

| Author |

Message |

Rosco663

Joined: 17 Dec 2012

Posts: 257

Location: South Australia

|

Posted: Fri Feb 08, 2013 4:26 am Post subject: Removing wooden coachwork without flames... Posted: Fri Feb 08, 2013 4:26 am Post subject: Removing wooden coachwork without flames... |

|

|

While removing the wooden coachwork frame from the chassis of my Series 1 Morris 8/40 Tourer, it was found that many of the machine screws/coach bolts were seized into the captive nuts on the chassis.

One thing I should share with all those restoring a timber framed vehicle is that 70+ year old timber and flames do not mix. I quickly learnt not to use heat anywhere near the timber work as it is tinder dry and very easy to ignite!!  So my early attempts to use a butane torch to heat nuts to assist in removing bolts were quickly abandoned until the wood work was gone. So my early attempts to use a butane torch to heat nuts to assist in removing bolts were quickly abandoned until the wood work was gone.

After some trial and error the following steps were adopted.

The first thing I did was to wire buff the exposed threads as much as possible, (where accessible) then apply a liberal soaking of penetrating oil spray and allow this to soak in over some time.

I then used a screwdriver to loosen the screw. If this did not happen a sharp tap with a hammer on the end of the screwdriver whilst applying left hand torque worked on some of them. If still unsuccessful a wrench was used on the shank of the screwdriver whilst turning it (until the slot became mangled).

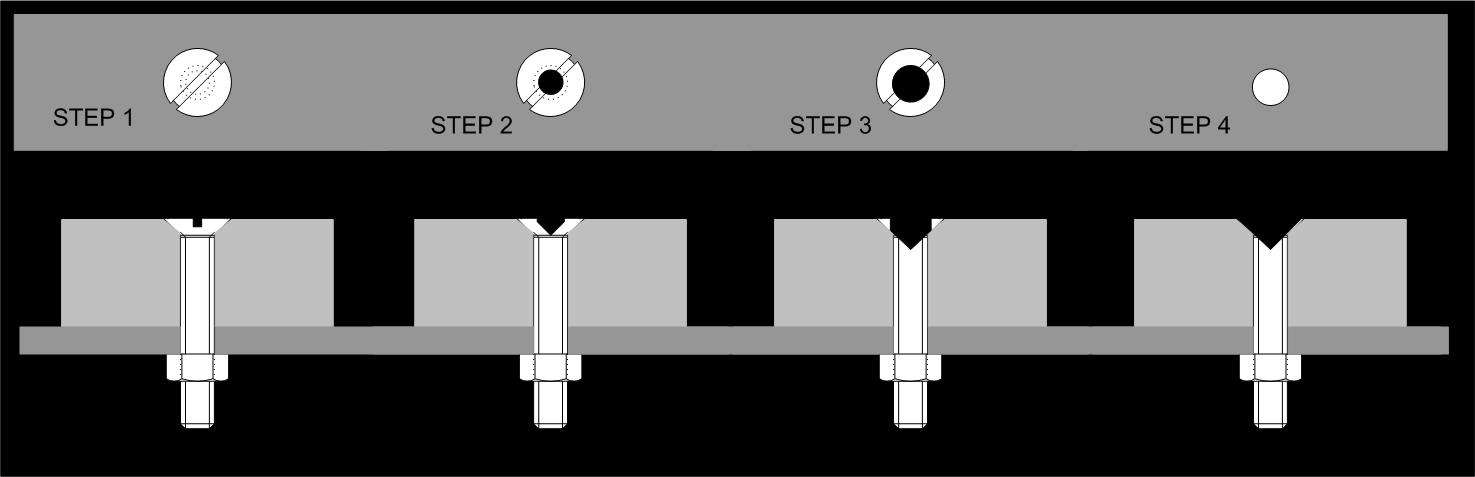

Referring to the following drawing the four steps indicated were applied to those stubborn screws that would not budge.

Step 1/ Not really a step at all just the initial condition.

Step2/ Centre punch the centre of the screw in the middle of the slot. Then use a small drill to make a pilot hole dead centre of the screw.

Step 3/ Use a drill as close in diameter as the shank of the screw and ground to the angle of the countersink (you will need a sample screw to do this). Then carefully drill out the top of the countersink - you will know when this is deep enough as the remains of the screw head will spin off and up the shank of the drill bit.

Step 4/ When you have removed the countersink from the screw head the timber is then able to be lifted off.

Above shows that minimal timber is removed (and no blackened scorch marks  ). ).

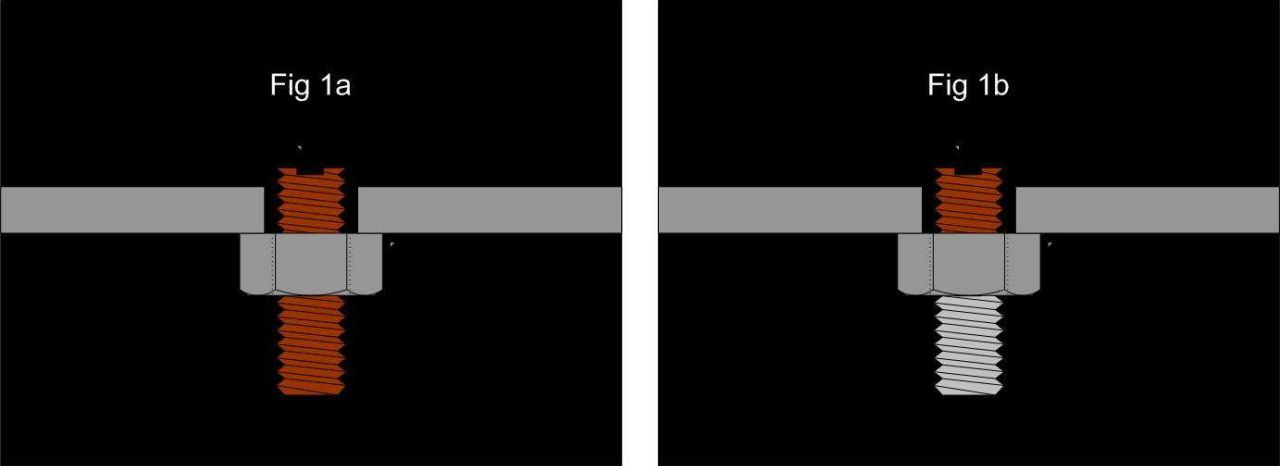

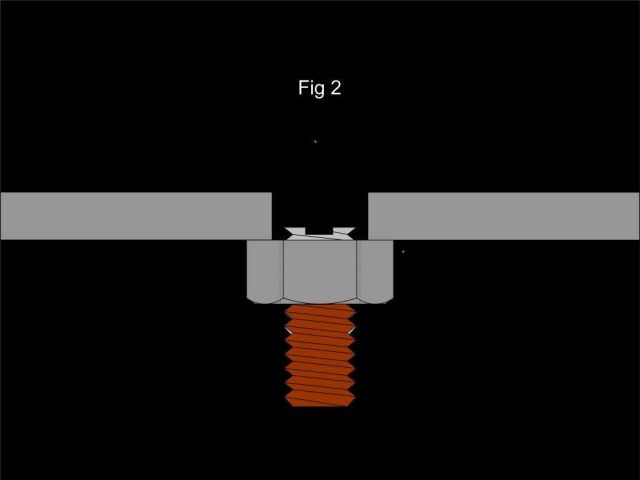

It was then very easy to deal with the studs that remained. Just a simple matter of heating the captive bolt with the butane torch, a quick spray with WD40 in the threaded section and at the same time cooling the stud with a spray of cold water (using a cheap supermarket bought spray bottle). Then using a pair of vice grips unthreaded the stud.

BTW the El Cheapo spray bottle was used to put out my first smoldering timber incident whilst using an angle grinder and cut off disc on the running board coach bolts during their removal.

During this process a few sheared off above the chassis and were of sufficient length to cut a new slot in the top with a hacksaw. Then run a die tap up the underneath as far as possible and attempt to unscrew from the top.

And for those that sheared off flush these were best threaded out by gripping below the captive nut with vice grips then unthreaded. The threads inside are usually protected from corrosion by the nut and the burr will generally straighten out without causing too much grief. A quick run through with the thread tap will fix this.

Cheers

_________________

Rosco |

|

| Back to top |

|

|

PAUL BEAUMONT

Joined: 27 Nov 2007

Posts: 1281

Location: Barnsley S. Yorks

|

Posted: Fri Feb 08, 2013 2:21 pm Post subject: Posted: Fri Feb 08, 2013 2:21 pm Post subject: |

|

|

| I find that the intelligent use of a Dremel can work wonders on jobs like this. I have had great success carefully cutting rusted nuts in half and actually leaving the fastener reuseable. |

|

| Back to top |

|

|

ajlelectronics

Joined: 04 Oct 2010

Posts: 168

Location: Gloucester

|

Posted: Fri Feb 08, 2013 2:34 pm Post subject: Posted: Fri Feb 08, 2013 2:34 pm Post subject: |

|

|

You would probably gain some benefit from using a good penetrating oil. There is little point in using a water displacement fluid for the job.

_________________

Evans Waterless Coolants

Find this and more at http://www.classicmicrocars.com

Sat TV / Aerial systems etc: http://www.ajlelectronics.co.uk |

|

| Back to top |

|

|

Penman

Joined: 23 Nov 2007

Posts: 4761

Location: Swindon, Wilts.

|

Posted: Fri Feb 08, 2013 3:05 pm Post subject: Posted: Fri Feb 08, 2013 3:05 pm Post subject: |

|

|

Hi

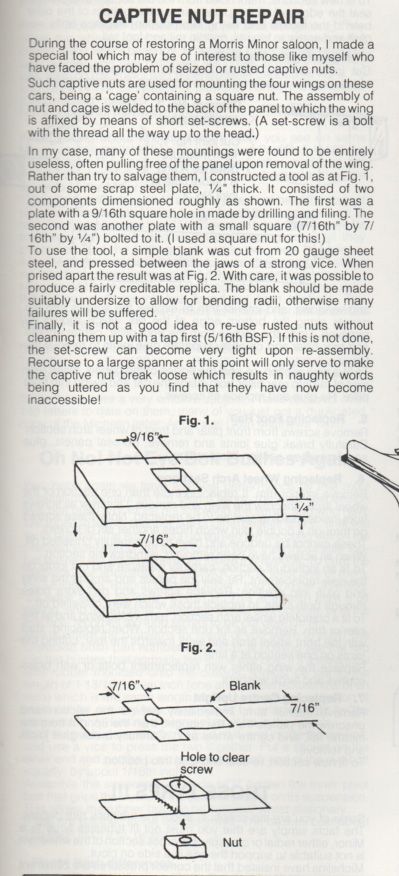

I found this in MMOC's Minor Matters.

Dimensions might have to be altered to suit other vehicles.

_________________

Bristols should always come in pairs.

Any 2 from:-

Straight 6

V8 V10 |

|

| Back to top |

|

|

Rosco663

Joined: 17 Dec 2012

Posts: 257

Location: South Australia

|

Posted: Sat Feb 09, 2013 2:20 am Post subject: Posted: Sat Feb 09, 2013 2:20 am Post subject: |

|

|

| ajlelectronics wrote: | | You would probably gain some benefit from using a good penetrating oil. There is little point in using a water displacement fluid for the job. |

I probably would. Do you have any suggestions to share?

_________________

Rosco |

|

| Back to top |

|

|

Bitumen Boy

Joined: 26 Jan 2012

Posts: 1735

Location: Above the snow line in old Monmouthshire

|

Posted: Sat Feb 09, 2013 8:27 pm Post subject: Posted: Sat Feb 09, 2013 8:27 pm Post subject: |

|

|

Plusgas takes a lot of beating - not the easiest to find but well worth the effort, though what the situation might be where you are..? Earlier this week the guy next door handed me a box of rusty old tools that were going to the tip if I didn't want them. Included were several pairs of old pliers, all rusted up solid. A little plusgas later all are moving, and following some light oil all but one are moving freely, the awkward one is gradually freeing up with more plusgas. I learnt many years ago that you can't have too many pliers as they always seem to disappear when you want them (Stanley knives, similar) and have salvaged counless pairs over the last few years that were either free or cost pennies because they were seized  |

|

| Back to top |

|

|

welshrover

Joined: 09 Aug 2011

Posts: 326

|

Posted: Sat Feb 09, 2013 10:31 pm Post subject: Posted: Sat Feb 09, 2013 10:31 pm Post subject: |

|

|

i use atf and acetone mixed together. not had nowt yet that as beaten it ..  |

|

| Back to top |

|

|

Rich5ltr

Joined: 28 Mar 2008

Posts: 678

Location: Hampshire, UK

|

Posted: Sat Feb 09, 2013 11:11 pm Post subject: Posted: Sat Feb 09, 2013 11:11 pm Post subject: |

|

|

| As much as I love and admire pre-war and wooden framed cars, I take my hat of to you for having the patience and dedication to do this, it would drive me mad! I guess that make me respect your work at shows even more when I see it. Thanks for posting this! |

|

| Back to top |

|

|

Rosco663

Joined: 17 Dec 2012

Posts: 257

Location: South Australia

|

Posted: Wed Feb 13, 2013 2:52 am Post subject: Posted: Wed Feb 13, 2013 2:52 am Post subject: |

|

|

Thanks one and all for your comments/suggestions.

Couldn't get any PlusGas but a 50/50 mix of acetone and auto tranny fluid works a treat. Wish I had heard that one earlier.

Ane thing is for certain I will not be getting flames anywhere near this mixture.......

_________________

Rosco |

|

| Back to top |

|

|

buzzy bee

Joined: 23 Nov 2007

Posts: 3382

Location: South Cheshire

|

Posted: Wed Feb 13, 2013 5:55 pm Post subject: Posted: Wed Feb 13, 2013 5:55 pm Post subject: |

|

|

Hi

As dicey as it sounds there is at times no option but to use heat, I was working on a Thrashing box recently, which was in a similar tinder dry state, and with a bit of water applied in certain area's, tin being used etc to deflect the flames, I got all fittings out, all fittings remained intact too, as they were to be re used with the let in timbers further along the area. I do agree it was not the nicest feeling using it though.

Morris Lubricants do a decent penetrating oil.

You might also be surprise how much a hot air gun can do to help matters, then you are not playing with fire so to speak.

Cheers

Dave |

|

| Back to top |

|

|

ukdave2002

Joined: 23 Nov 2007

Posts: 4105

Location: South Cheshire

|

Posted: Wed Feb 13, 2013 6:21 pm Post subject: Posted: Wed Feb 13, 2013 6:21 pm Post subject: |

|

|

Left handed drill bits can be quite useful especially with studs in blind holes, pick a size that's smaller than the stud, and the drilling action and heat often screws the broken stud out

Trouble is I'm right handed

Dave |

|

| Back to top |

|

|

|