|

|

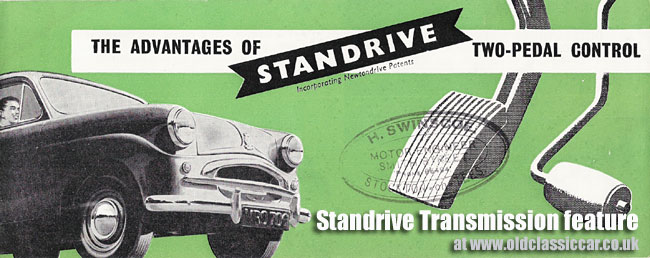

| See Homepage. | This page: Information featured in a 1950s leaflet published by the Standard Motor Co. Ltd. |

Standrive (incorporating Newtondrive patents).From 2003 to 2005 I owned a Standard 10 fitted with the now-rare Standrive transmission, and I thought it was brilliant. Admittedly, I didn't have any problems with it, so didn't have to delve too deeply into it's workings, and if I had, perhaps I'd not be so keen now!

While I owned it, I searched all over for material and information on the Standrive system, just in case things we wrong, then at least I'd have a fighting chance of being able to do something about it. Most of the material I found went with the car in 2005, but I still have this small leaflet, that introduced the system to a slightly sceptical motoring public. It is only a 2 page production, and details the key benefits of this 2 pedal arrangement. The clutch pedal went, and was replaced with a push button on top of the gearlever instead. This button activated the clutch, in order that another ratio could be selected while on the move - when stationary, there was no need to use the clutch button. | |

|

The info in the leaflet may be of interest to other owners of Standrive-equipped cars out there, which went as follows:

| |

|

Outstanding Advantages The elimination of the clutch pedal - the most difficult control to operate...

To sum up, with the new "Standrive" you have all the best features of the conventional gear change, but with the added advantage of smoother, safer, less fatiguing driving in all traffic conditions, and its simplicity of operation should particularly appeal to women drivers and all users of vehicles in conditions requiring frequent gear changes.

It consists of three major components: a centrifugal automatic clutch, a servo operated withdrawal cylinder and a control valve unit. The combination of these components allows gear changes to be made simply by moving the gear lever. The central gearlever is fitted with an electric switch incorporated in the gear lever head and operated by a push button. All that is necessary when making a gear change is to press the button on top of the gear lever and move the lever through the normal gate. The sequence of operations to drive the car away from stationary and bring it to rest again are as follows: With the gear in neutral and hand brake applied, the engine is started in the normal way. With the engine idling, the gear lever is moved into the required gear (for all normal starts 2nd is preferable). All that is then required to move off is for the engine to be accelerated, and as the drive is smoothly taken up the handbrake released in the usual way. To change up into the next higher gear, the gear lever is moved into the next appropriate gear, the electric switch on the gear lever being automatically depressed at the same time by the weight of the hand on the gear lever knob. The engine speed during this operation is automatically controlled to ensure a smooth change. To change to a lower gear, the foot is kept on the accelerator pedal and the gear lever is moved as before, but to the next lowest gear required. The change will be instantaneous and completely smooth and noiseless. The mechanism again automatically controlling the synchronisation of throttle and clutch. To stop, the accelerator is released and the brake applied. The car will stop with the engine idling. If a stop is of more than short duration the gearlever is placed in neutral ready to move into the starting position. Issued by The Standard Motor Company Ltd, Coventry, England. So there you have it, the official benefits of the 2 pedal transmission as outlined by the Standard factory in the mid/late 1950s. I think the installation in my car had been simplified slightly, in that the throttle wasn't automatically blipped during downchanges, which the above infers should happen. However a little blip on the throttle by the right foot kept the changes smooth enough, if not exactly seamless. I believe similar systems appeared on other cars of the fifties, for example on some Morris cars, where it was badged as the Manumatic. |

|

|

Custom Search

|

|

| Old Classic Car (C) R. Jones 2025. Content not to be reproduced elsewhere. |

| Website by ableweb. |

| Privacy Policy, Cookies & Disclaimers |