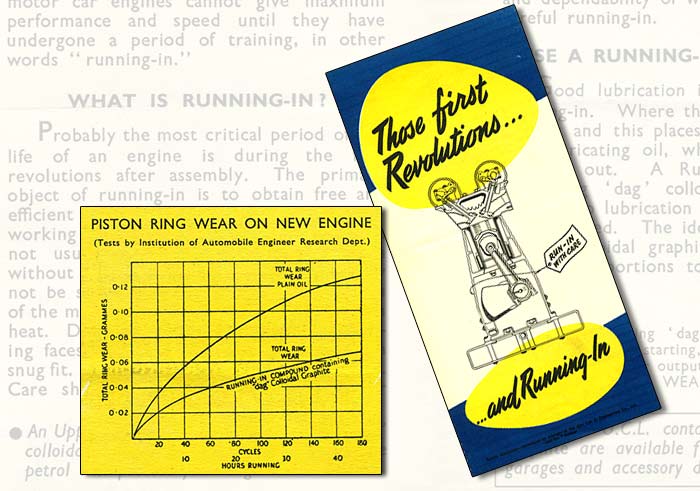

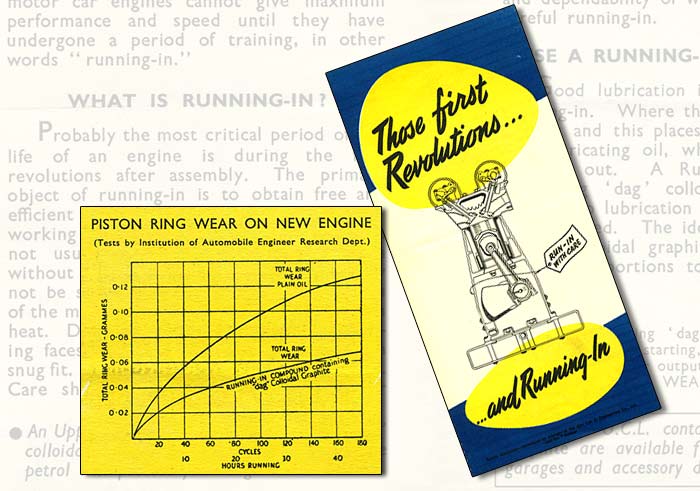

DAG Colloidal Graphite running-in compounds.

This leaflet dates to the late 1940s, and was issued by Acheson Colloids Limited of London, the company behind "DAG" Colloidal Graphite. This substance was a constituent of engine products made by Edward Joy & Sons Ltd, Leeds. The latter produced Colloidal "Petroyle", and "Filtrate" Running-In Compound. Both were designed to minimise engine wear on newly-rebuilt engines.

|

|

|

The cover shows a simple cutaway drawing of a contemporary engine - not just any old engine, but a twin overhead cam unit built by the Alta Car & Engineering Company Limited. Inside, the reader is taken through some of the issues facing a car-owner who has a new engine under the bonnet of his or her motor-car...at one time "Running In Please Pass" signs were a common sight in the back windows of cars, but I've not seen one for years (other than the old Castrol one I've got in the back of my A40 that is). The leaflet explains things as follows:

|

|

"The successful athlete is trained to a high degree of perfection so that he is able to respond to maximum effort when called upon to do so. Flexibility and speed of movement without stiffness is the result of such careful preparation. Like athletes, motor car engines cannot give maximum performance and speed until they have undergone a period of training, in other words: running in."

|

What is Running-In?

"Probably the most critical period of the life of an engine is during the first revolutions after assembly. The primary object of running-in is to obtain free and efficient action of working parts. The working surfaces when newly assembled are not usually smooth enough to function without undue friction, while clearances may not be sufficient to take up the expansion of the metal due to frictional and combustion heat. During running-in the opposite working faces polish one another and acquire a snug fit. Such a process must not he hurried. Care should be taken to follow the car manufacturer's recommendations, and to use a good running-in compound. The longer time a car owner takes to run-in his engine and the more carefully it is done, the longer will be its life. He will be well rewarded by an engine the fine performance and dependability of which is the result of careful running in.

|

Use a Running-In compound.

"Good lubrication is essential to good running-in. Where there is friction there is heat and this places an added strain on the lubricating oil, which will have been thinned out. A running-in compound containing "dag" colloidal graphite gives support to lubrication at a time when it is most needed. The ideal is achieved when "dag" colloidal graphite is added in the correct proportions the the recommended motor oil."

|

Why "Colloidal" Graphite?

"Colloidal Graphite produced by the Acheson process is made from selected materials of high purity and divided up into particles so fine that a special type of microscope is needed to see them. When a material is reduced to this extreme fineness it is said to be "colloidalised". Hence the expression "colloidal" graphite.

|

|

A running-in compound containing "dag" colloidal graphite will protect your engine and control the rate of wear whilst it is being run-in. By the use of "dag" colloidal graphite the "conditioning" of all working surfacces will be achieved with the minimum of wear, thus ensuring that your engine will begin its active life with the bearings, cylinders and pistons in as perfect a condition as possible."

|

|

The leaflet then mentions that R.I.C. (Running-In Compound) and U.C.L. (Upper Cylinder Lubricant) both containing "dag" could be purchased from your local Halfords, as well as other accessory dealers and roadside garages.

|

|

Return to the motoring collectables section of the site.

|